Real Time Location Systems

The knowledge of where assets are located within a physical space is a fundamental element for the digitalization of processes occurring in these environments. RTLS technologies provide this information, with varying characteristics depending on the chosen technology.

With over 65,000 tracked assets and more than 15 years of field experience in diverse RTLS projects, Thinkin is the ideal partner to support companies in adopting cutting-edge RTLS systems.

These systems enable enhanced visibility, optimization of internal processes, and the introduction of advanced automation.

Over the years, we have integrated various RTLS technologies, offering localization accuracy that ranges from a few centimeters to several meters, depending on the scenario. There is no right or wrong technology—only one that is more or less suitable for the project's objectives.

Scalability must be designed from the start: at Thinkin, we have the ability to envision the development of a project over time and identify the best solution to support its growth.

Seamless Connection with ERP, MES, and WMS

How does a Real-Time Locating System work?

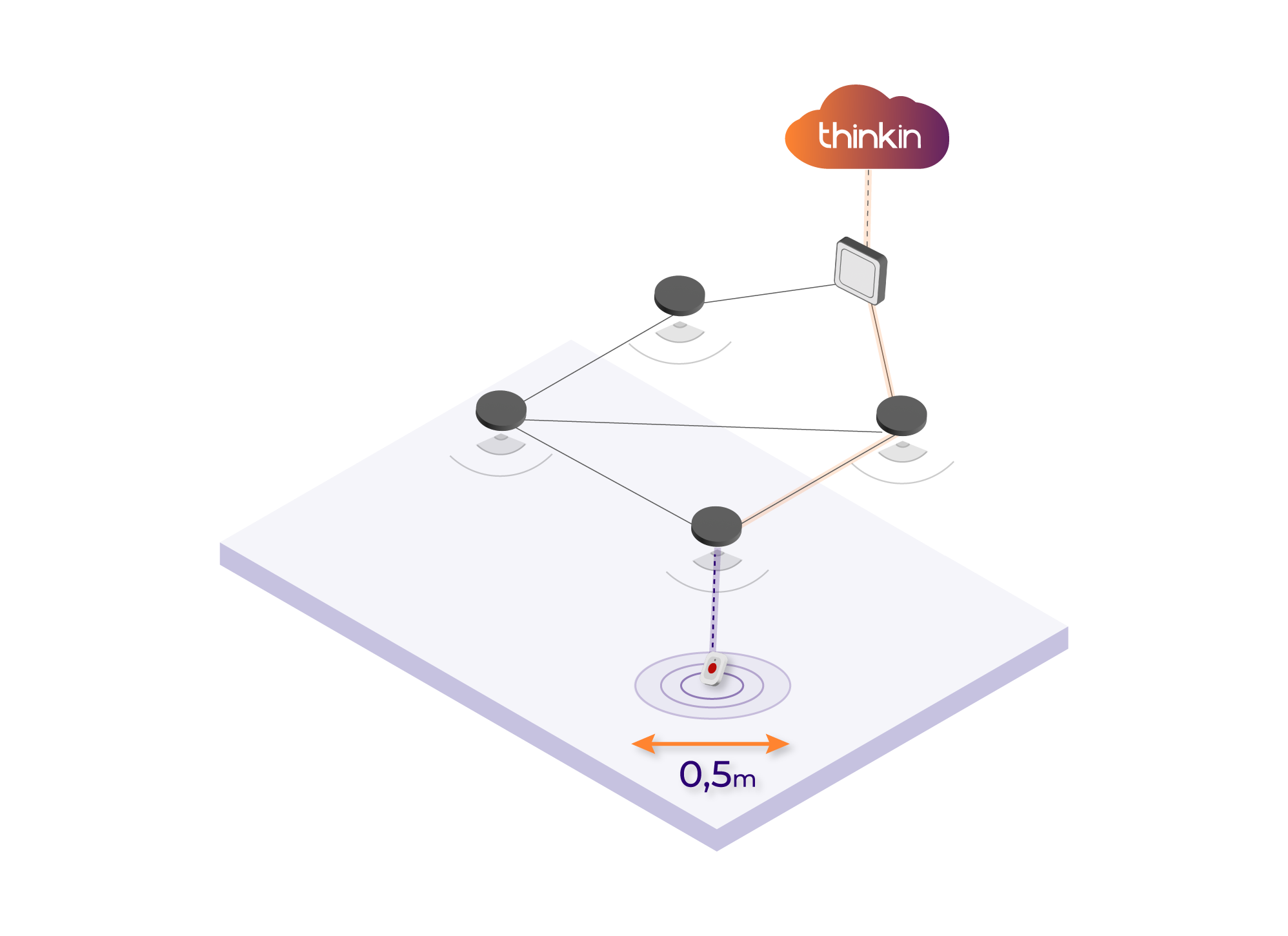

Real-Time Locating Systems (RTLS) are technologies that enable real-time tracking of assets within a monitored area, both in indoor and outdoor spaces. RTLS systems typically consist of:

-

TAGs:

These are electronic devices powered either by battery or continuously, attached to the asset to be located. TAGs transmit a radio frequency signal that is processed by antennas within the TAG's communication range. -

Antennas:

The monitored area is equipped with antennas, which can be either wired or battery-powered depending on the chosen technology. The antennas receive signals from the TAGs, process them locally, and transmit the data to a localization software. -

Localization Software:

Dedicated software calculates the position of the TAG based on the signals received from the antennas. Depending on the technology and algorithm used, the accuracy can range from 5 meters to a few centimeters, and the position update frequency can vary from a few minutes to just a few milliseconds.

How to choose the most suitable RTLS Technology?

The correct selection of an RTLS technology is crucial and represents a fundamental step in any RTLS project. There is no localization technology that is inherently more or less performant; rather, each technology is appropriate for a specific application or industrial scenario.

This is why identifying the most suitable localization technology requires a careful assessment of the use case to be implemented, considering the environment in which the RTLS system will be installed, as well as multiple functional and non-functional requirements.

Available RTLS Technologies and Evaluation Criteria

Several technologies are available on the market for indoor localization. While they share some common elements, they differ in various aspects. Therefore, there are specific criteria that help evaluate RTLS technologies and facilitate the final choice.

Key Evaluation Criteria:

-

Accuracy:

Different RTLS technologies offer accuracy levels ranging from a few centimeters to 5 meters. For critical projects, technologies such as UWB (Ultra-Wideband) can guarantee accuracy up to 10 cm. -

Number of Tracked Assets:

From managing a few vehicles in a warehouse to tracking thousands of carts in a supermarket, Thinkin offers scalable solutions tailored to specific needs. -

Operating Environment:

Environmental conditions and layout significantly influence the choice of technology. We assist in configuring optimal solutions even in complex environments. -

Costs:

The evaluation includes not only the initial investment but also long-term operational costs. Our experience ensures optimal ROI by selecting the most cost-effective solutions. For further insights, read our blog: RTLS: how to choose the right technology

Relying on qualified professionals is essential to ensure the reliability of RTLS-based software. An incorrectly sized RTLS system, improper antenna calibration, or inadequate edge server configuration can compromise the proper functioning of the system, resulting in inaccurate and unreliable process information.

RTLS systems are based on different location technologies, including Wi-Fi, Bluetooth Low Energy (BLE), Ultra-Wideband (UWB) and infrared. Each technology has specific characteristics, such as accuracy, required infrastructure and cost, which determine its suitability for certain scenarios. Thinkin helps you understand and choose the most suitable technology.

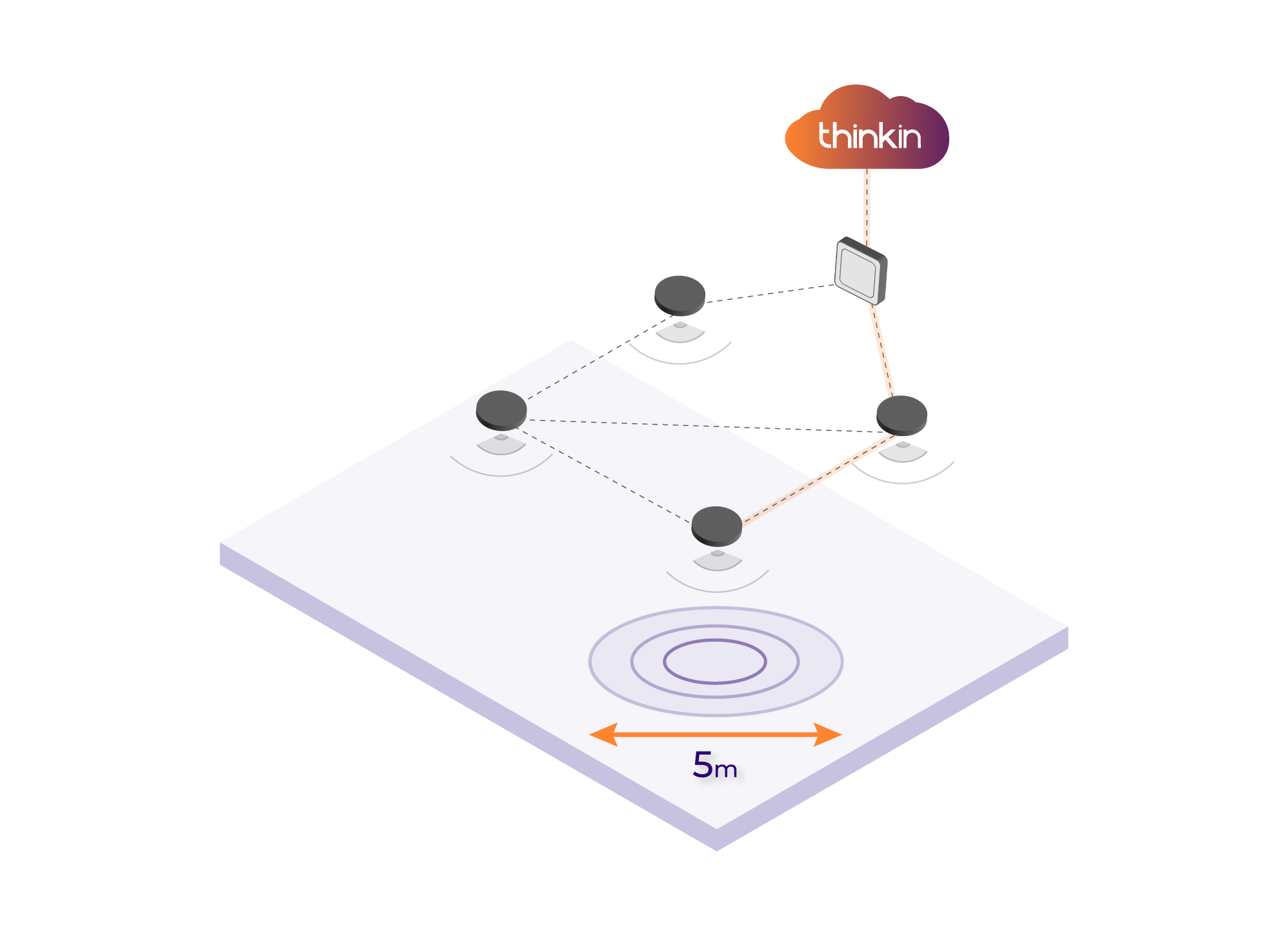

Accuracy:

- Up to 5 meters

Latency:

- 1-5 minutes

Infrastructure:

- Battery-powered anchors

- Internet-connected gateways

- Cloud-based localization engine

Key Benefits:

- No wiring required

- Low maintenance costs

- Low total cost of ownership

- Spatial scalability

Target Applications:

- Yard management

- Asset tracking

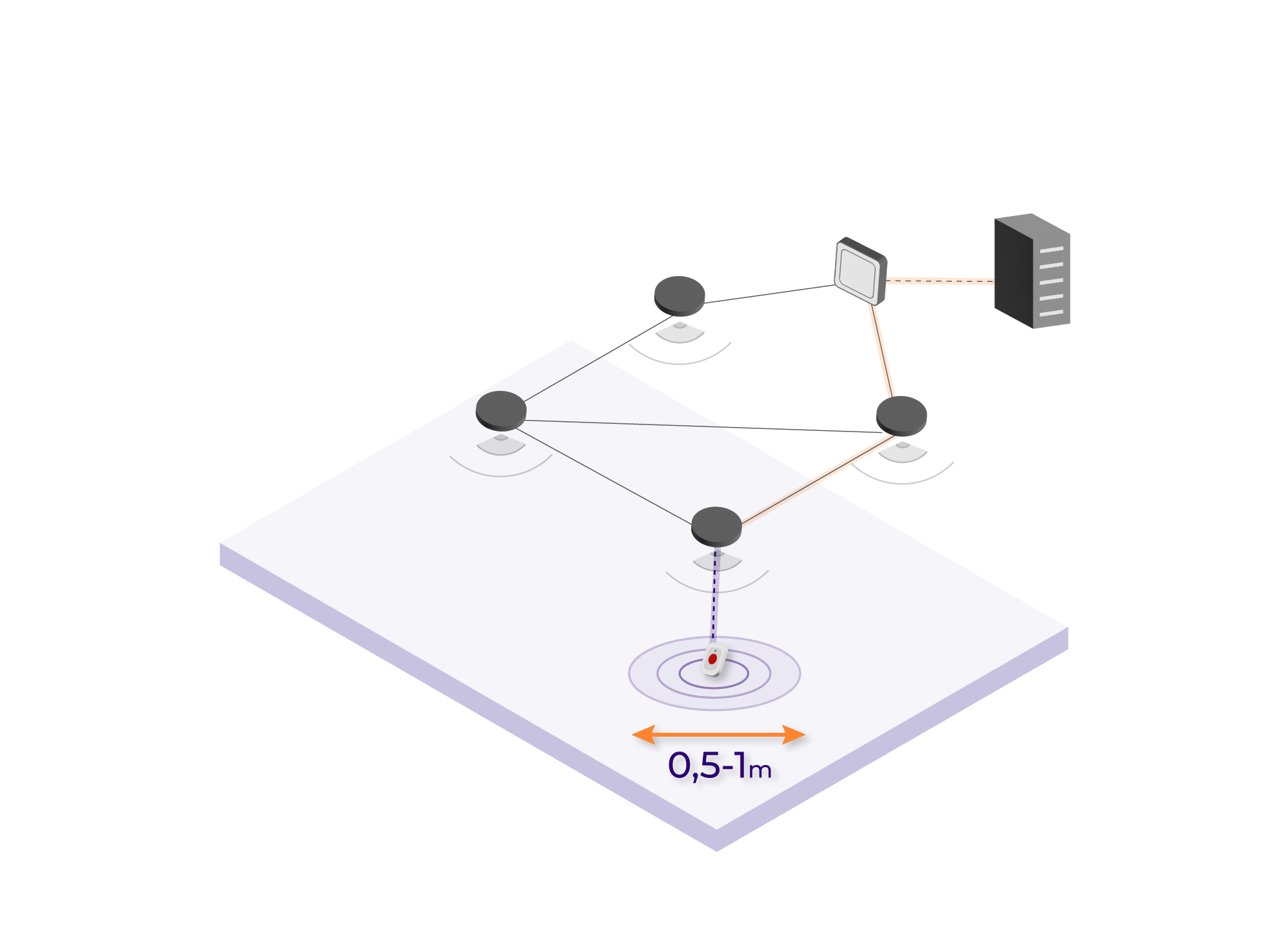

Accuracy:

- 0.5-1 meter

Latency:

- Less than 1 second

Infrastructure:

- Wired anchors (PoE)

- Battery-powered TAGs

- Edge-based localization engine (on-premises)

Key Benefits:

- High precision

- Robustness

- Long TAG lifespan

- Spatial scalability

Target Applications:

- Asset tracking

- Work-in-progress (WIP) monitoring and control

- Safety

Accuracy:

- 0.5 meters

Latency:

- Less than 1 second

Infrastructure:

- Wired anchors (PoE)

- Battery-powered TAGs

- Cloud-based localization engine

Key Benefits:

- High precision

- Robustness

- Reliable positioning

Target Applications:

- Asset tracking

- WIP (Work-In-Progress) monitoring and control

- Safety

Direct Tracking vs. Indirect Tracking

Indirect tracking uses the position of an already monitored device (e.g., forklifts or mobile devices) to indirectly associate the location of the assets being moved or managed.

- Via forklift: An RTLS system detects the position of the forklift and associates it with the assets being moved, allowing indirect monitoring of all goods in the warehouse or production area.

- Via mobile device: The position of the device used for operations such as picking or putaway is geo-located through RTLS, automatically associating the location with the managed asset.

Advantages:

- Lower hardware costs, as tags are not applied directly to each asset.

- Reuse of devices and reduction of operational waste.

Direct tracking involves installing a tag directly on the asset to be monitored. This allows the exact position of the asset to be detected and visualized in real time through the Thinkin platform, accessible via a simple browser. It is ideal for ensuring continuous and immediate visibility of critical assets, reducing the risk of losses or inefficiencies.

Advantages:

- Each asset has a dedicated tag, offering precision and reliability in tracking.

- The position is always available in real time on the platform.

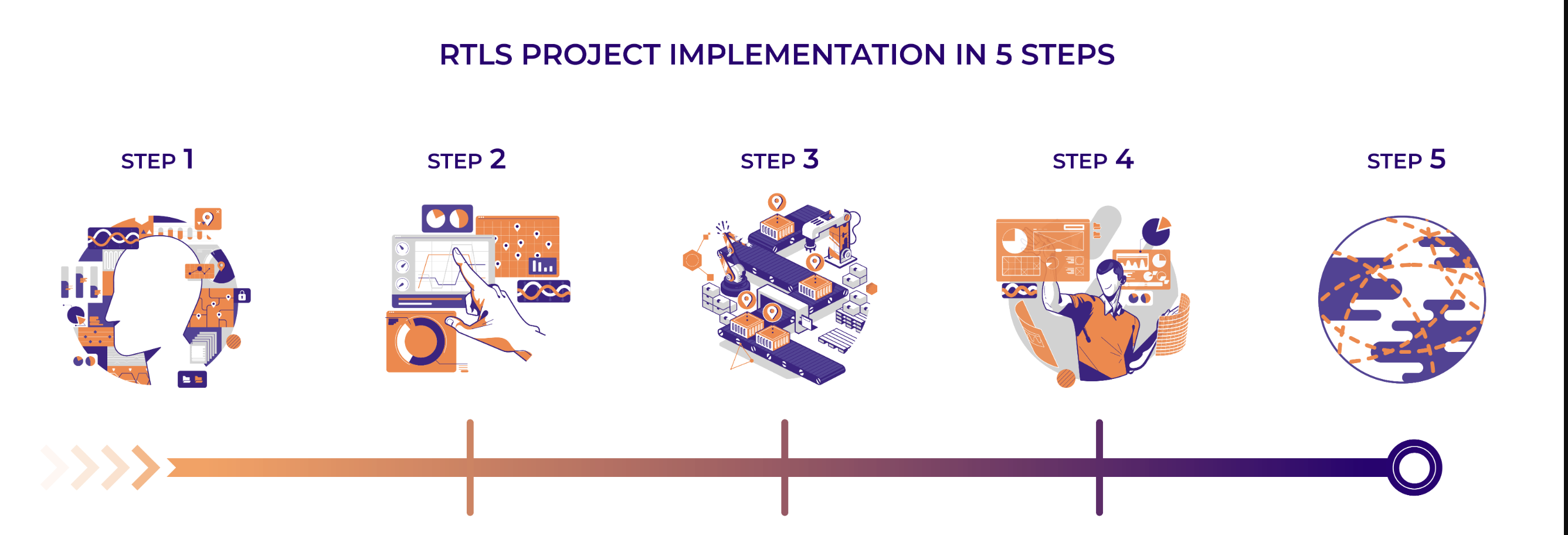

Enter your details and download our infographic with the 5 steps for an RTLS project.