RTLS and RFID: integration is the winning weapon

Technologies such as RTLS and RFID are becoming increasingly important for companies seeking to improve their efficiency and traceability of assets and processes. Find out how integrating them brings greater benefits.

- RTLS and RFID are different but perfectly complementary technologies

- Indirect tracking underpins the integration of RTLS and RFID

- Integration of RTLS and RFID supports a complete solution with greater benefits

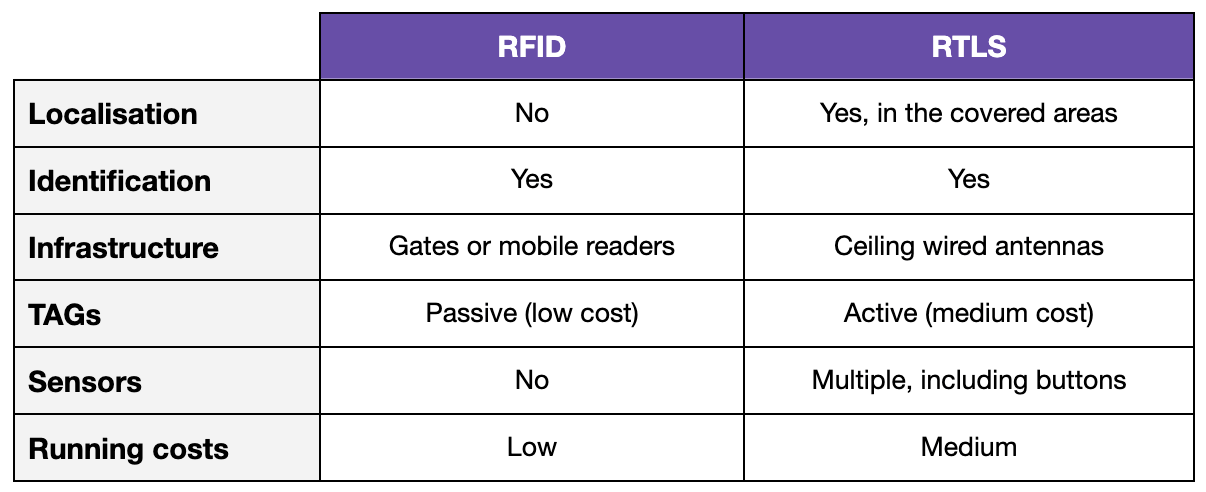

The integration of RTLS and RFID technologies is becoming increasingly important for companies seeking to improve their efficiency and traceability of assets and processes. The role of these two technologies is typically complementary: RFID is primarily used to quickly identify objects at specific read points, while RTLS provides information about their location over time. The integration of these technologies makes it possible to combine the advantages of both systems and provide solutions for complete traceability of industrial workflows and processes.

RTLS vs RFID: the two technologies compared

RFID, from Radio Frequency Identification, is a radio frequency identification technology and is able to detect objects and people uniquely and massively. Electronic tags, or TAGs, uniquely identify the tracked objects, storing related data. The information contained in the TAGs is then read by "reader" devices either manually or is detected directly by RFID gates, thus enabling the detection of the passage of an item in a given area.

RFID systems are extremely effective in reading the presence of items, even very small ones, at specific reading points. These reading points can be fixed (e.g., gates) or dynamic (handheld readers). However, when an RFID tagged object is not at one of these points, it is invisible to the system. In addition, RFID TAGs must be positioned correctly for proper reading.

RTLS stands for Real-Time Locating System, which is a technology that can locate objects and people in real-time, even in indoor settings. RTLS systems are based on a hardware infrastructure that consists of small devices of different shapes and sizes, called TAGs, which are associated with the objects being tracked.

Fixed receivers installed on ceilings or walls receive the signal emanating from TAGs as they move within the space, thus enabling their precise localisation in space, and real-time monitoring of everything happening in the structure.

RTLS systems thus enable continuous localisation of an object in two dimensions, over even very large spaces. This allows a much more flexible management of services and processes. In addition, RTLS TAGs are active devices that can be used for a very large number of services and applications.

RTLS and RFID: Unity is strength

RTLS and RFID technologies offer numerous advantages, especially when used in an integrated way. Let's see some example cases where the use of both technologies leads to important results in terms of process efficiency and warehouse as well as inventory management.

Tracking of (many) very small objects

In the case of small objects (e.g., hospital vial), it is not possible to use an RTLS TAG that is typically too large size-wise. However, often these objects are then moved by means of assets that can be tracked by RTLS. Using RFID TAGs to identify the objects and RTLS to track the means indirectly allows you to know where the objects are in space and thus to have complete visibility into the path of these objects.

This use case has applications in various fields including healthcare, intra-logistics, and many others.

Indirect tracking

Indirect tracking refers to the mechanism by which we track the location of one object by the location of another. This type of tracking is typically used in warehouses, where it is not possible to track via RTLS all stored objects due to their numbers. Instead, it is preferred to track the forklift that is used to move goods and use an RFID reader on the forklift to identify the item being moved. In this way, by attaching an RFID TAG to the tracked goods and an RTLS TAG to the forklifts, it is possible to have complete visibility of the status of the warehouse and accurately and automatically track the movement of the goods present. This solution allows for:

- Dynamic warehouse management: since workers are aware of the location of tracked goods in real-time, they can be placed in the most convenient location in the warehouse at a given time, rather than having a fixed location within the facility. As a result, efficiency is greatly improved and available space is fully optimised.

- Complete inventory visibility: complete real-time visibility and tracking of the entire inventory is guaranteed, enabling warehouse managers to quickly and easily locate specific items and track their movement within the warehouse. This leads to reduced storage costs and improved responsiveness to changes in market demand through more efficient use of resources.

In summary, it can be stated that RTLS and RFID have differences, although they remain not exclusive, but rather complementary. Indeed, RFID has a limitation in the accuracy of tracking assets. While RFID is undoubtedly essential for knowing whether a given object is present or has moved in a given area or department, it is only through RTLS that the exact location can be tracked in real-time, wherever it is within the facility. After all, it is precisely the lower accuracy of RFID, which makes the devices and related infrastructure more cost-effective than RTLS. Therefore, here's where the integration of RTLS and RFID comes into play to make the best out of both technologies, creating room for valuable advantages.