OUR MISSION

"We create the digital twin of your infrastructure.

We provide you visibility and control over all your assets and processes. We follow you through all phases, from design and initial validation to implementation of the final solution"

Whether it is a shopping cart, a work order or a hospital bed, ThinkIN® provides the ability to quickly search and track any asset and identify its location in real time.

With the data collected, ThinkIN® provides you with a tool for monitoring and analysing resources and processes to optimise your facility's strategic and operational activities.

We adapt our technologies and knowledge to provide you with efficient solutions tailored to your needs.

We analyse large volumes of data and derive the intelligence you need to support your strategic and operational decisions.

Our sectors

Industry 4.0

ThinkIN® offers a solution for the digitisation of manufacturing processes through the localisation, tracking and monitoring of assets (pallets, forklifts, materials, semi-finished goods or other).

ThinkIN® creates a digital twin of the manufacturing process to improve operational efficiency, maintenance and worker safety. Our services include Asset Management, Tool Management, E-Kanban and Andon Wirless.

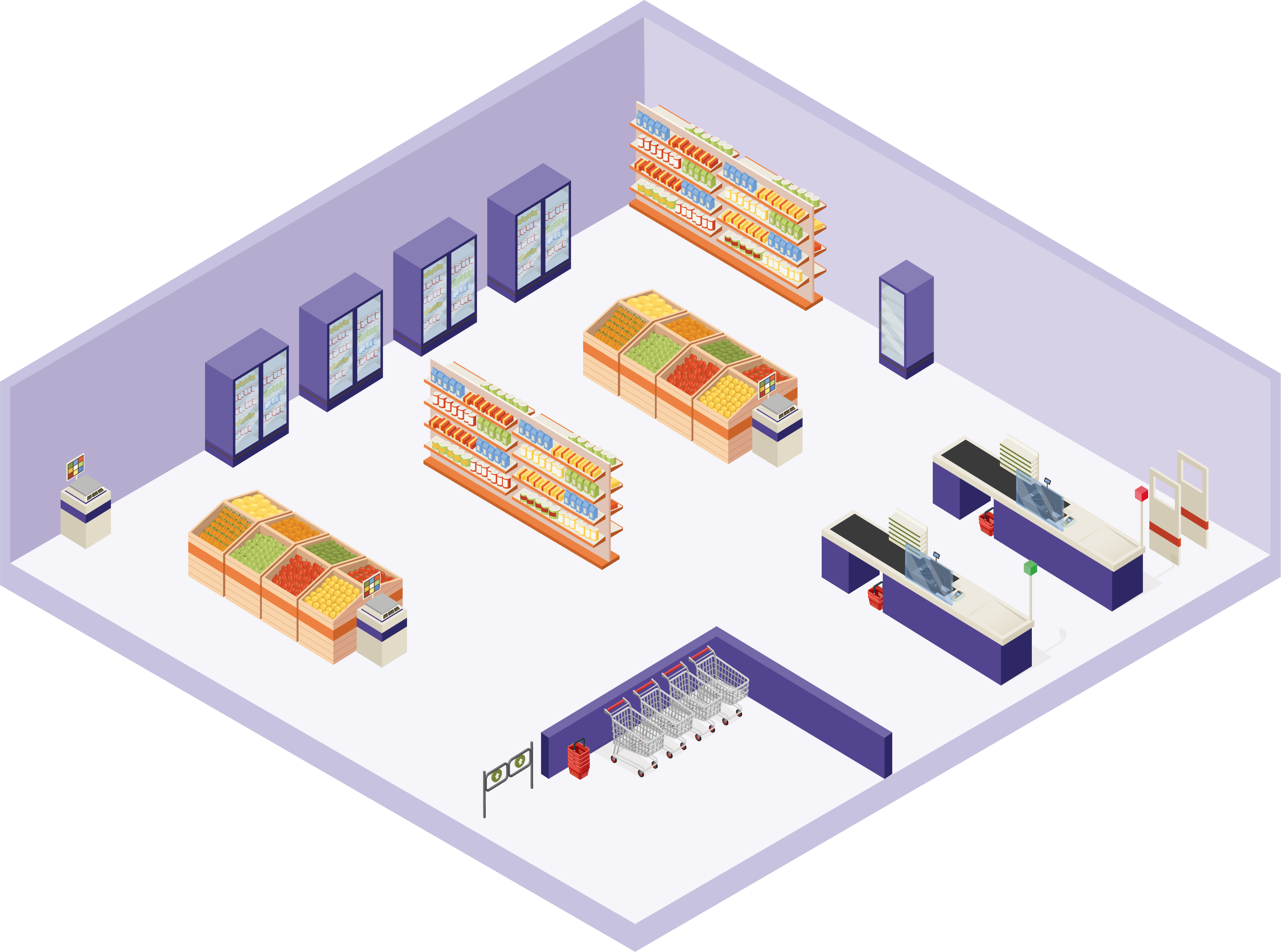

Retail

RetailerIN® is an in-store intelligence solution for supermarkets. Starting from the tracking of shopping carts, baskets, or smartphones - provided with a dedicated mobile application - RetailerIN® maps the full customer journey, making the physical store measurable and interactive just like in e-commerce.

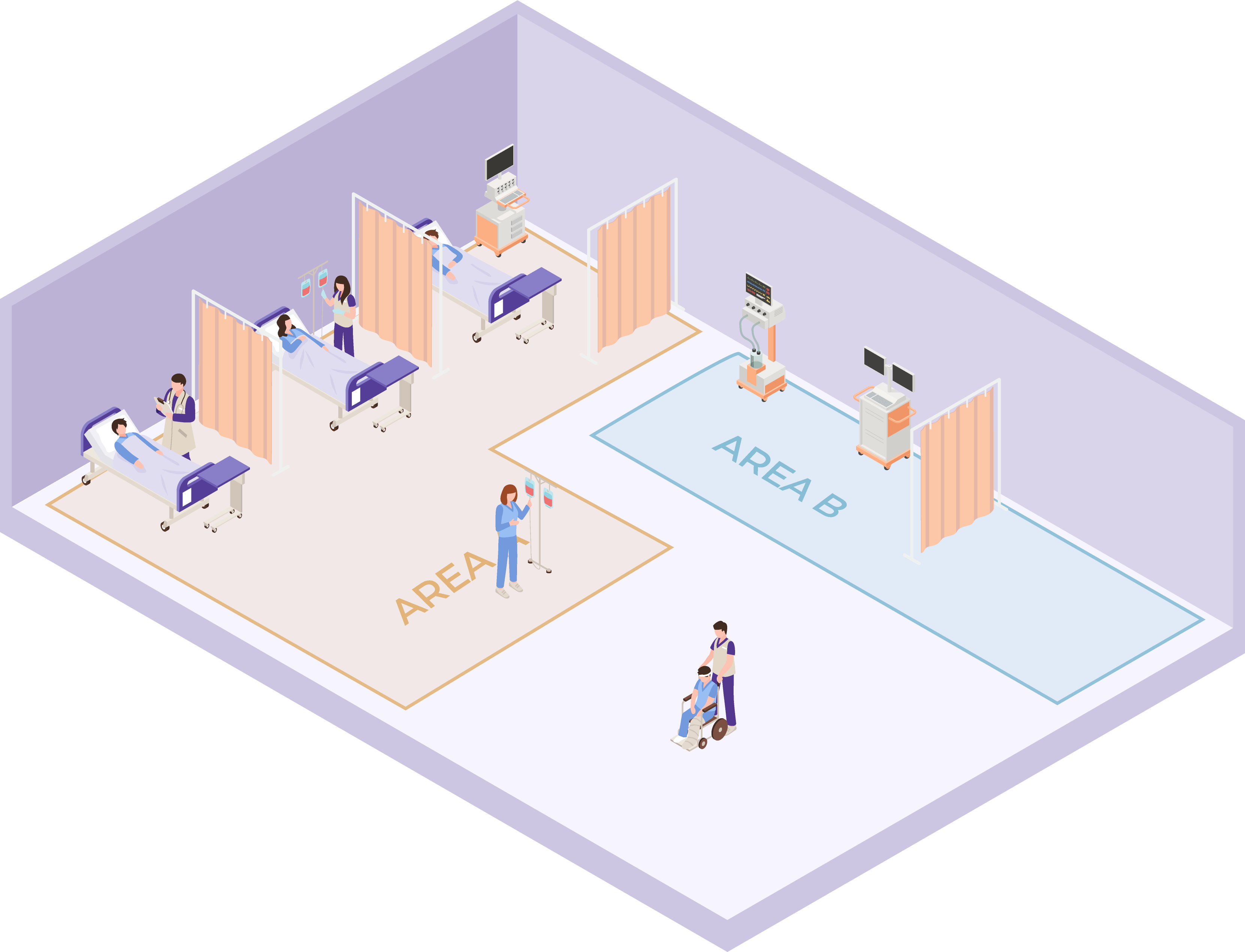

Healthcare

ThinkIN® is an asset tracking platform that allows healthcare providers to visualise on an interactive map where essential assets such as beds, wheelchairs, infusion pumps, biometric monitors, and more are located. This information is used to digitise and automate internal procedures, with a major impact on efficiency and resource savings.

Unable to find your sector?

PHASE 1

Technology Demonstration

We temporarily install our technology for one or a few days, allowing you to see it in action directly within your operational context. This enables you to concretely evaluate how it can enhance your processes and engage your team.

PHASE 2

The Pilot Project - Strategic Validation

We analyze your processes, define concrete objectives with clear performance indicators, and test the solution in a pilot area. We collect real data to optimize the system before scaling it across the entire company.

PHASE 3

Implementation and Validation

We adapt the solution tested during the pilot to your needs and implement it across the entire company. This phase includes adjustments based on the collected data and field tests to verify the results.

PHASE 4

Tailored Support

We provide you with ongoing technical support, integrations with your systems, and platform updates to meet evolving needs over time.

thinkin key numbers

Shopping sessions and asset movements

Km travelled by the assets we have tracked

We have customers and partners throughout the world

We support your business strategy and operations

Request a demo with no obligations. Tell us your needs, our experts will identify the best solution for you and you will be able to see a product demo.